Showing all 14 results

-

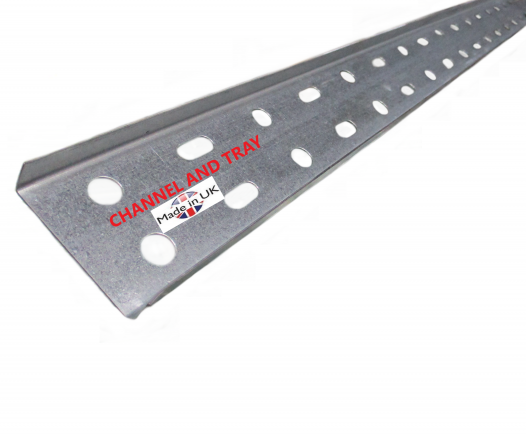

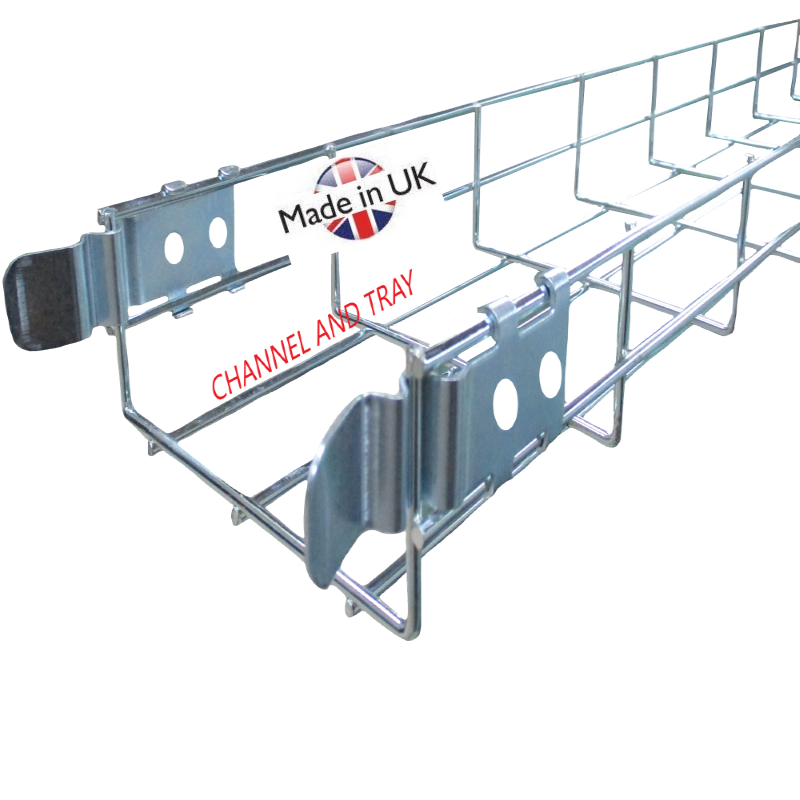

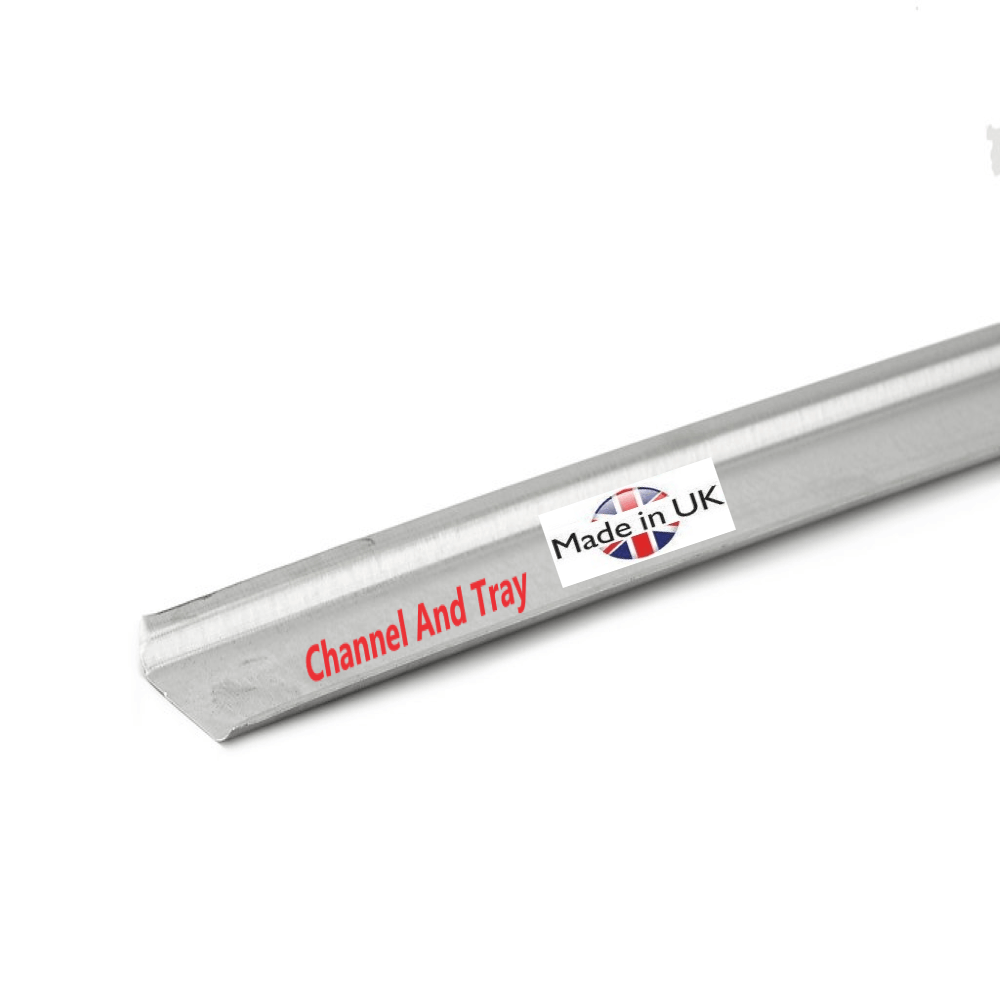

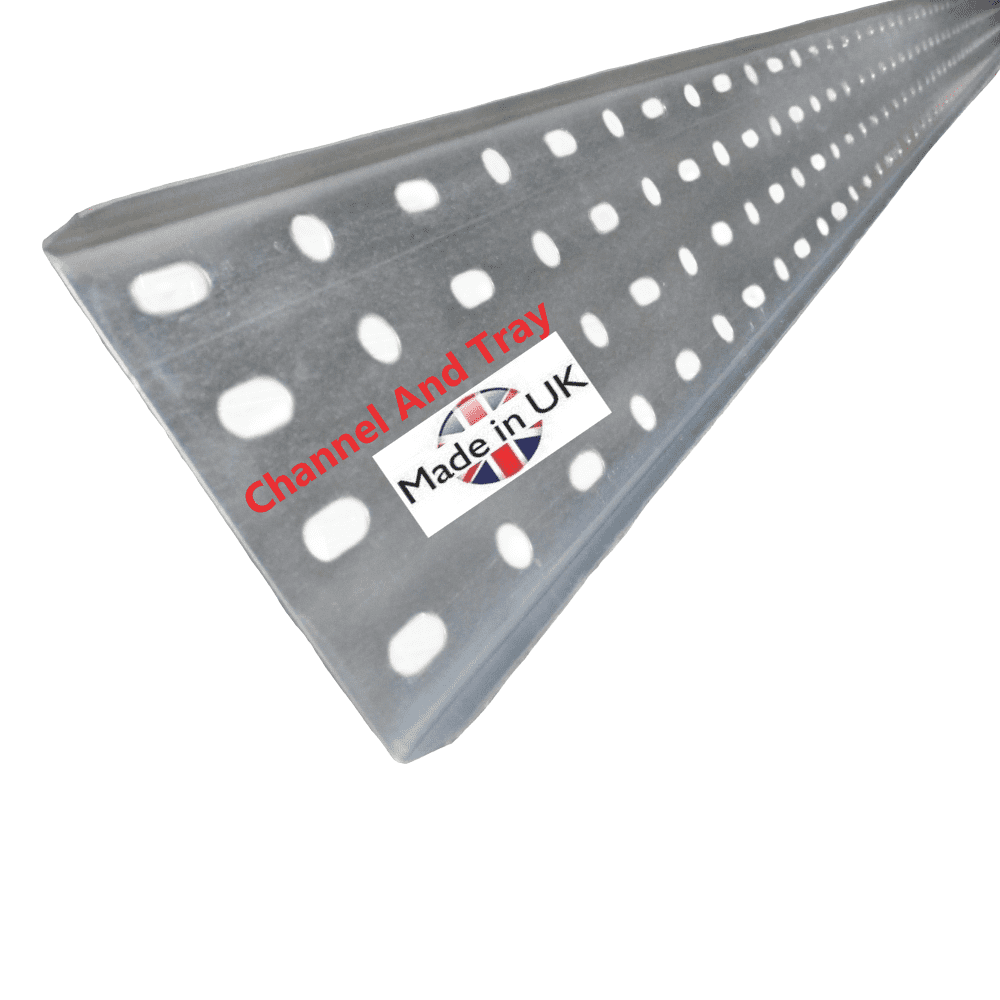

Metal Trunking

£13.05 – £26.00 -

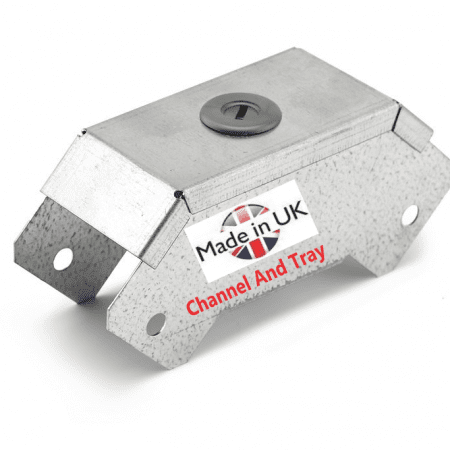

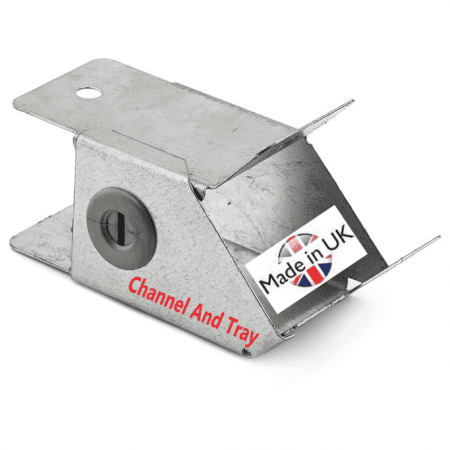

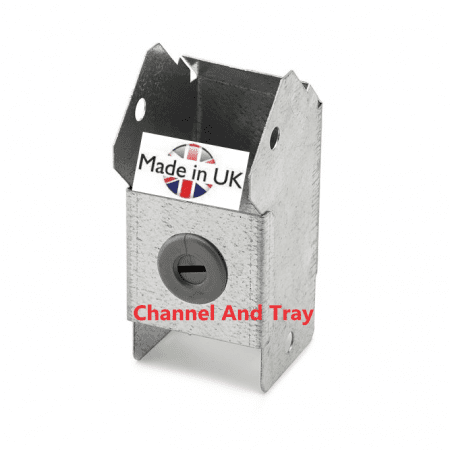

Trunking Coupler

£1.20 – £1.50 -

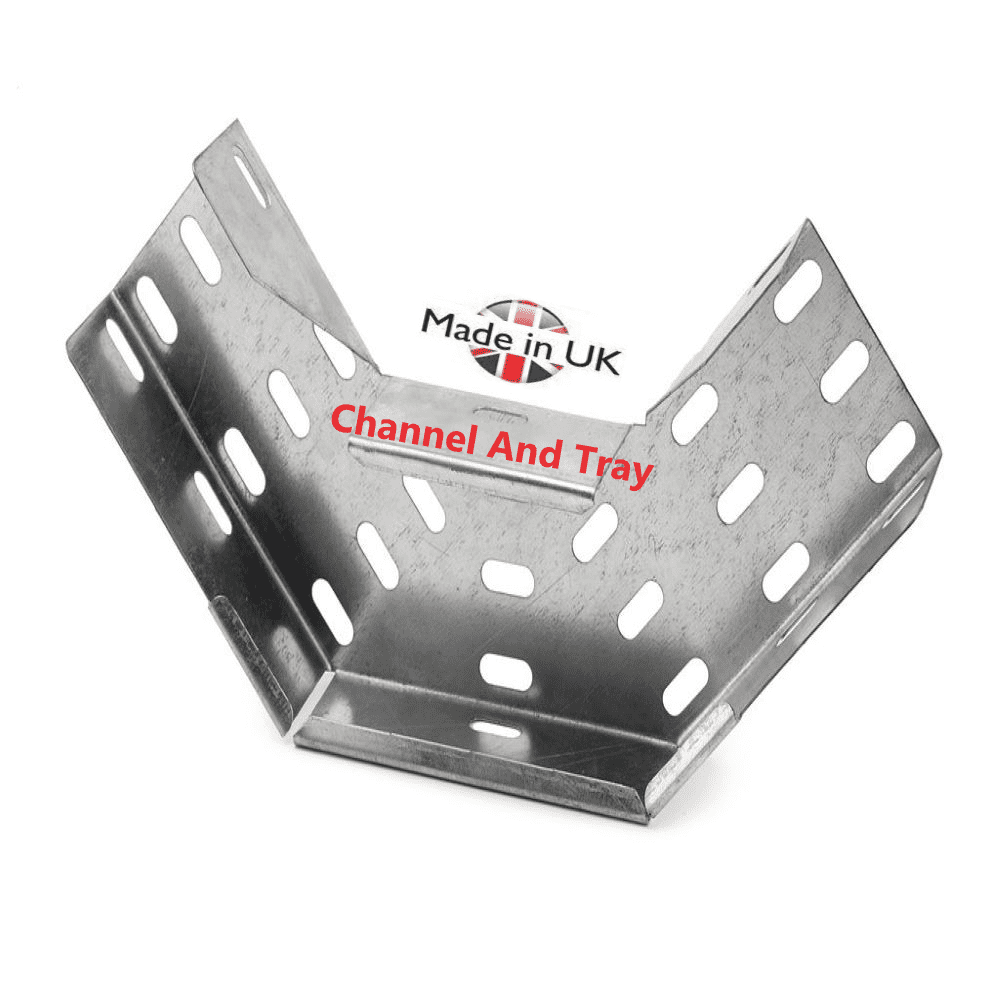

Trunking Top Lid 90 Degree Bend

£4.75 – £7.35 -

Trunking Inside Lid 90 Degree Bend

£4.75 – £7.35 -

Trunking Outside Lid 90 Degree Bend

£4.75 – £7.35 -

Trunking Top Lid 45 Degree Bend

£4.75 – £7.35 -

Trunking Inside Lid 45 Degree Bend

£4.75 – £7.35 -

Trunking Outside Lid 45 Degree Bend

£4.75 – £7.35 -

Trunking Top Lid Tee

£6.25 – £9.00 -

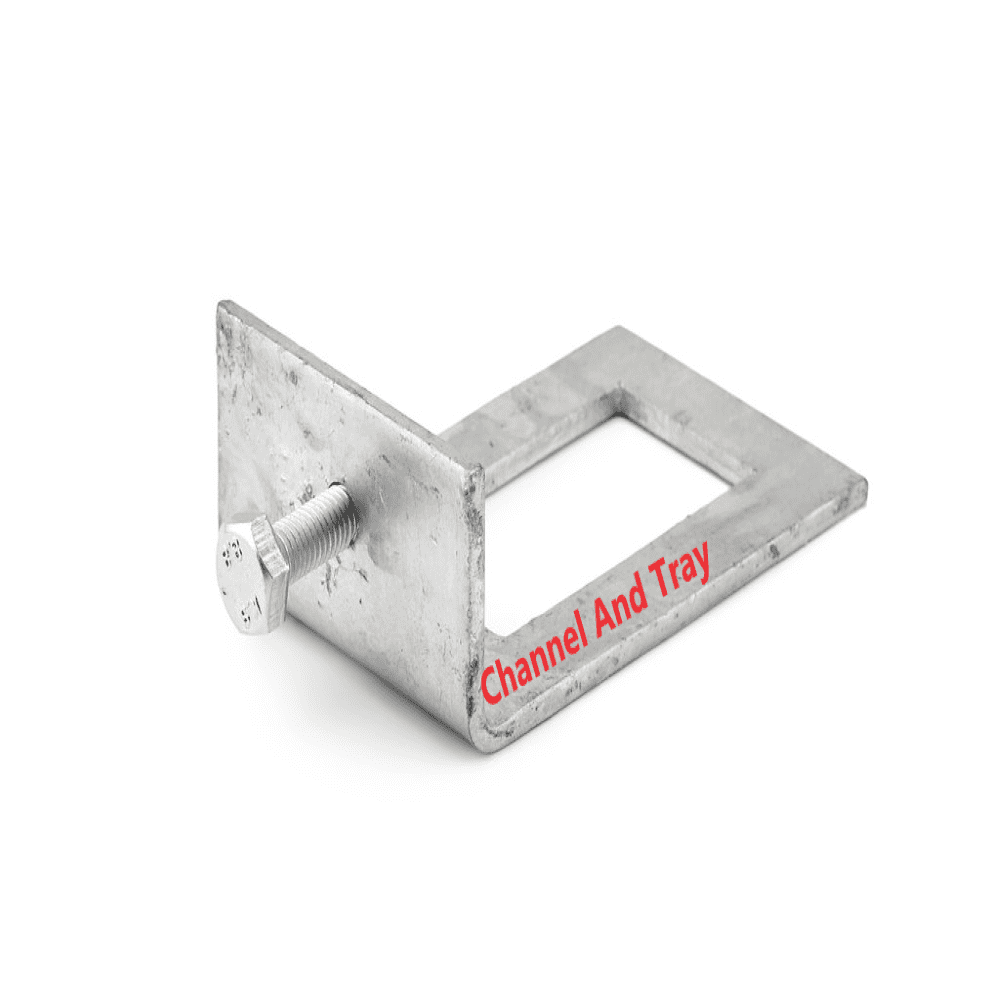

Trunking Suspension Hanger/Stirrup Hanger

£2.05 – £4.10 -

Trunking Reducer

£10.00 – £12.00 -

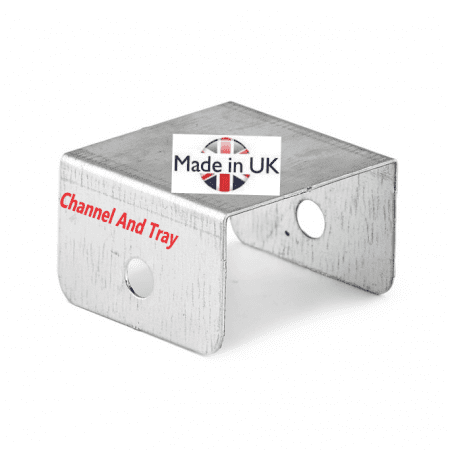

Trunking End Cap

£1.30 – £1.75 -

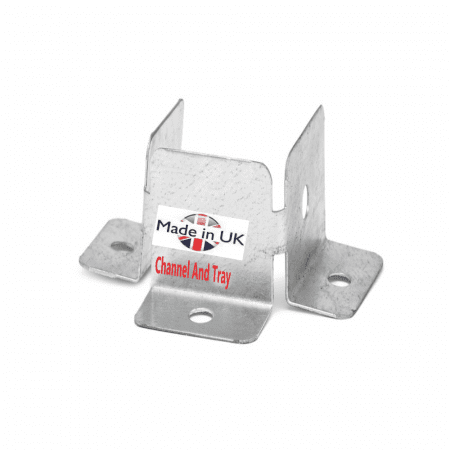

Trunking Flange Plate

£1.75 – £2.25 -

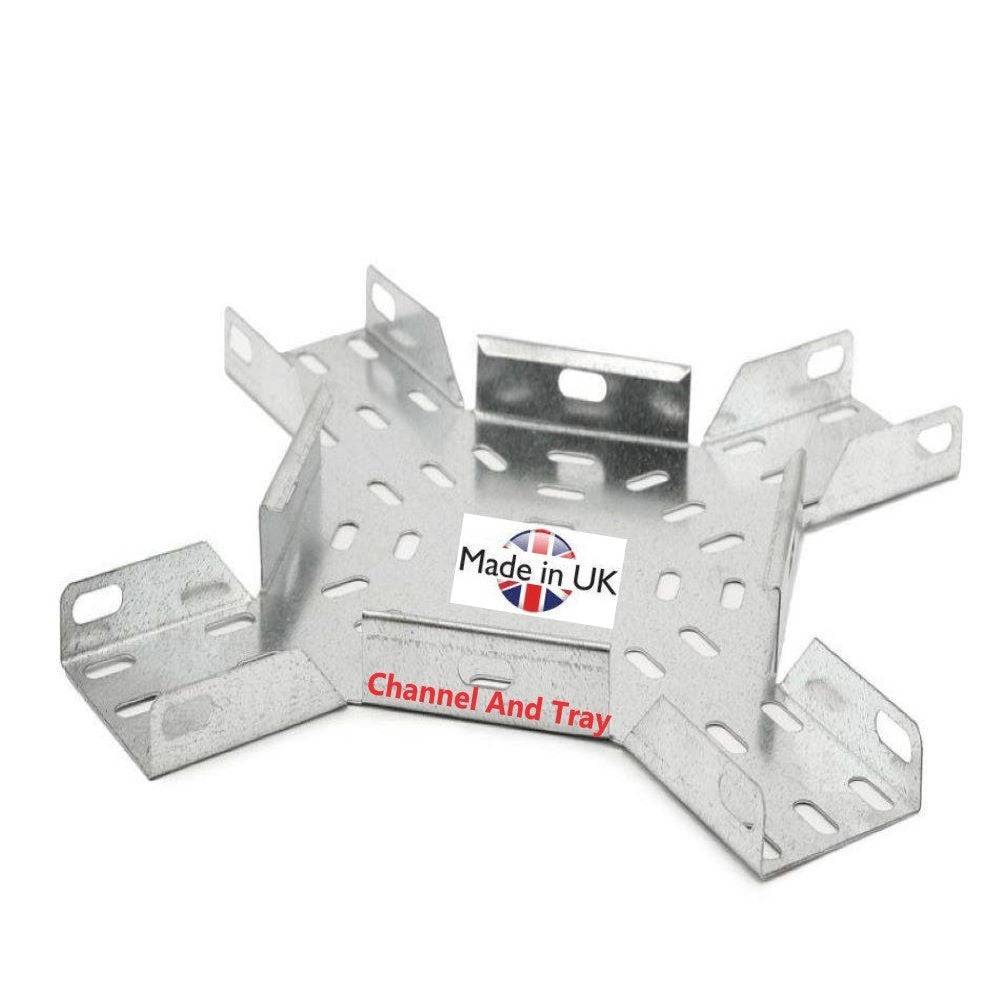

Trunking Fourway

£7.05 – £11.60

Metal Trunking Solutions by ChannelandTray

ChannelandTray is at the forefront of providing high-quality metal trunking systems that meet the diverse needs of various industries.

Understanding Metal Trunking

Metal Cable trunking is a robust and durable method of protecting and managing electrical cables. It consists of a series of metal channels that house cables, providing physical protection and organizing them neatly. This system is essential in environments where cables are susceptible to damage or where aesthetics and organization are priorities. Unlike plastic alternatives, Metal Cable trunking offers superior strength and durability, making it ideal for industrial settings where cables might be exposed to harsh conditions.

Advantages of Metal Trunking

ChannelandTray’s metal trunkings systems offer numerous advantages:

- Durability: Metal trunkings is resistant to wear and tear, ensuring a long lifespan even in demanding environments.

- Safety: By encasing cables, metal trunkings reduces the risk of electrical hazards and prevents accidental damage.

- Aesthetics: A well-organized cable system improves the visual appeal of a workspace, which is particularly important in office environments and public buildings.

- Flexibility: Metal cable trunking systems can be easily modified or expanded, accommodating changes in the number or type of cables without extensive rework.

- Fire Resistance: Metal trunkings provides a higher degree of fire resistance compared to plastic alternatives, enhancing overall safety.

Applications of Metal Cable Trunking

ChannelandTray’s metal cable trunking is versatile and can be used in a variety of settings:

- Commercial Buildings: For neat and secure cable management in offices, retail spaces, and public areas.

- Industrial Facilities: To protect cables from physical damage and maintain organization in factories, warehouses, and production facilities.

- Data Centers: To ensure high performance and reliability by organizing and protecting extensive cabling networks.

- Residential Buildings: For homeowners looking to upgrade their cable management systems with a durable and aesthetically pleasing solution.

Why Choose ChannelandTray?

ChannelandTray has established itself as a trusted provider of metal trunkings solutions, known for its commitment to quality and customer satisfaction. Here are some reasons why businesses and individuals choose ChannelandTray for their cable management needs:

- Quality Products: ChannelandTray’s metal cable trunking systems are manufactured using high-grade materials, ensuring they meet rigorous standards for strength and durability.

- Expertise: With years of experience in the industry, ChannelandTray’s team offers valuable insights and recommendations tailored to each client’s specific requirements.

- Customization: ChannelandTray provides customized metal trunking solutions, allowing clients to select the sizes, finishes, and configurations that best suit their needs.

- Customer Service: Exceptional customer service is a cornerstone of ChannelandTray’s business model, with a focus on responsiveness and support throughout the purchasing and installation process.

- Competitive Pricing: By combining quality with affordability, ChannelandTray ensures that clients receive excellent value for their investment.

Installation and Maintenance

Proper installation is key to maximizing the benefits of metal trunkings systems. ChannelandTray provides comprehensive installation guides and support to ensure that their products are correctly installed. Additionally, metal cable trunking requires minimal maintenance, which further enhances its appeal as a long-term cable management solution.