In today’s fast-paced world, efficient and safe electrical installations are more important than ever. From industrial facilities to commercial buildings and data centers, the demand for structured cable management solutions has increased significantly. One such solution that has become increasingly popular for modern electrical systems is bend basket cable trays. These versatile and cost-effective systems are essential for ensuring organized, safe, and accessible cable management. At Channelandtray, we specialize in providing high-quality cable tray solutions, including bend basket trays, designed to meet the ever-growing needs of contemporary electrical installations.

Overview Of Cable Trays

What Are Bend Basket Cable Trays?

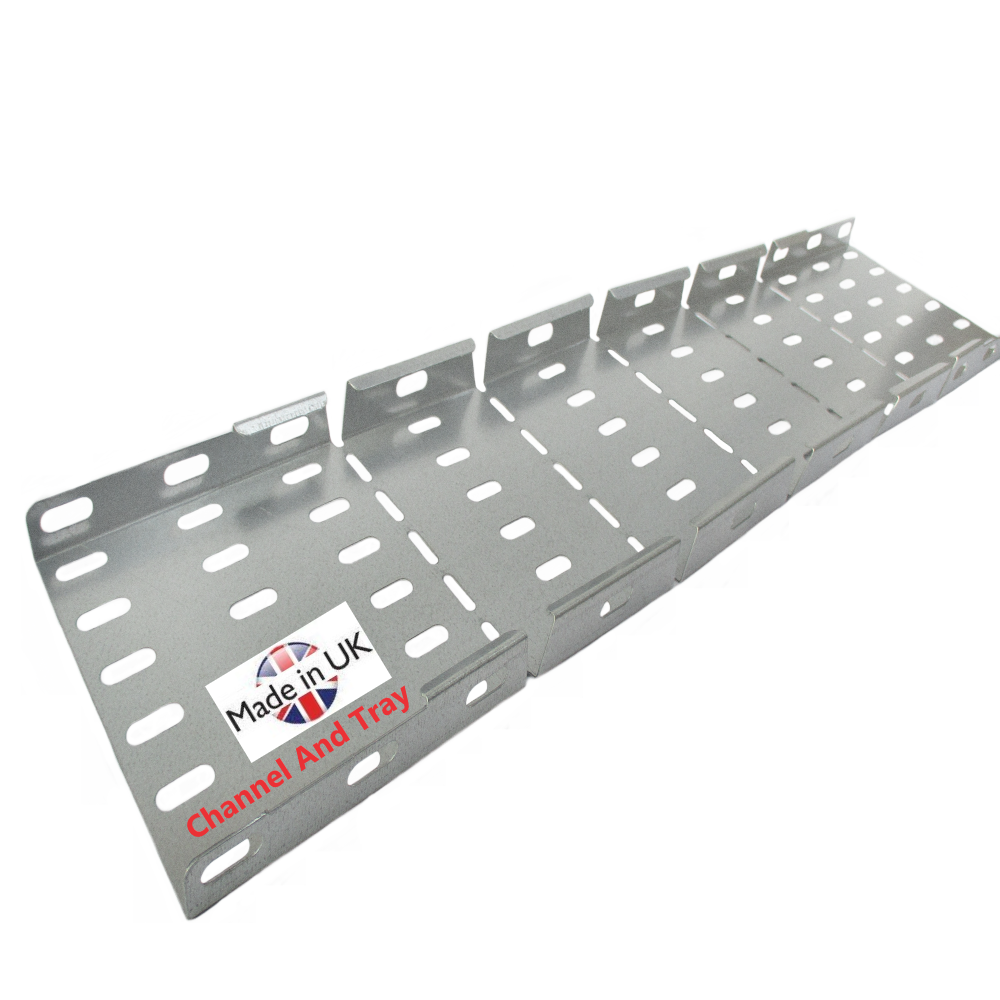

Bend basket cable trays are a type of cable management system that allows you to route cables in various directions, making them a crucial component in any modern electrical setup. Made from wire mesh or perforated metal, these trays are designed to support and organize cables while also providing the flexibility to change the direction of cable pathways. As the name suggests, the “bend” feature allows the trays to navigate corners or other obstructions, ensuring smooth transitions throughout the installation process.

Why Are Bend Basket Cable Trays Important?

Efficient Cable Management Proper cable management is essential for any electrical installation, whether residential, commercial, or industrial. Bend basket trays help organize cables in a structured manner, preventing tangles, reducing clutter, and ensuring that cables are securely held in place. This efficiency helps reduce the risk of damage to wires and ensures that future maintenance or upgrades are much easier.

Flexibility and Adaptability One of the standout features of bend basket trays is their ability to bend and adjust to various layouts. Whether you’re installing a new electrical system or upgrading an existing one, bend basket trays can easily accommodate changes in direction, making them ideal for complex installations with tight spaces or numerous obstacles. This adaptability is particularly beneficial in environments where space is limited, like data centers or industrial facilities.

Ease of Installation and Maintenance Bend basket trays simplify the installation process due to their lightweight, modular design. Unlike traditional conduit systems, which can be bulky and difficult to install, bend baskets are easy to cut, adjust, and assemble, reducing both time and labor costs. Furthermore, their open design provides quick access to cables for maintenance or troubleshooting, making repairs, upgrades, or replacements straightforward and efficient.

Enhanced Safety Safety is always a top priority in electrical installations, and bend basket cable trays help ensure that wiring systems are both safe and secure. The open structure of these trays allows for better ventilation and airflow, which helps prevent overheating of cables—a common cause of electrical hazards. Additionally, these trays prevent physical damage to wires, reducing the risk of short circuits or fire hazards.

Cost-Effective Solution The affordability of bend basket cable trays is another reason why they have gained widespread popularity in electrical installations. Their simple yet durable design eliminates the need for expensive fittings and hardware, making them an economical option for managing large networks of cables. They also reduce labor costs due to their easy installation, helping contractors and businesses keep expenses down.

Aesthetic Appeal In modern commercial and residential installations, aesthetics play a crucial role. Bend basket trays offer a sleek and unobtrusive design that fits seamlessly into the environment. Their clean lines and efficient cable organization not only help maintain an organized and professional appearance but also reduce visual clutter in spaces with open ceilings or exposed cable systems.

Applications of Bend Basket Cable Trays

Bend basket cable trays are versatile and can be used in a variety of settings:

Industrial Settings: Large manufacturing plants or power plants require robust cable management solutions that can withstand heavy-duty applications. Bend basket trays are ideal for routing and protecting cables in these demanding environments.

Commercial Buildings: From office buildings to shopping malls, bend basket trays are perfect for managing power, communication, and data cables in complex and high-traffic commercial spaces.

Data Centers: In data centers, where countless cables are used to connect servers and network equipment, bend basket cable trays are essential for maintaining order and preventing cable tangling or damage.

Residential Installations: Even in high-end residential buildings or multi-unit housing projects, bend basket trays help ensure that electrical and data cables are neatly routed, reducing clutter and increasing safety.

Benefits at a Glance:

- Easy Installation and Modularity: No need for complicated bending tools or additional fittings.

- Durability: Constructed from high-quality materials, ensuring longevity and minimal maintenance.

- Airflow & Cooling: The open design improves ventilation, keeping cables cool and preventing overheating.

- Adaptability: Easily bends to fit complex layouts and changing installation needs.

- Organized & Safe: Keeps cables secure and accessible, reducing the risk of damage and fire hazards.

Conclusion

In a world where electrical systems are becoming increasingly complex and expansive, basket cable trays provide an essential solution for efficient, safe, and cost-effective cable management. Their flexibility, ease of installation, and long-term durability make them a top choice for modern electrical installations across a range of industries. At Channelandtray, we offer high-quality bend basket cable trays that help you create organized, safe, and efficient electrical systems. Whether you are designing a new installation or upgrading an existing one, our products are built to meet the demands of today’s electrical infrastructure.

For more information on our cable management solutions, contact us at Channelandtray today and let us assist you in creating a streamlined, professional electrical installation.